Ultimate Guide to DTF Printing Methods for Spectacular Textile Layouts

Beginning on the journey of mastering DTF printing techniques can open up a globe of opportunities for producing visually captivating fabric styles. In this guide, we will discover the complex details of DTF printing, from grasping the basic essentials to unraveling advanced shade strategies that can raise your designs to brand-new heights.

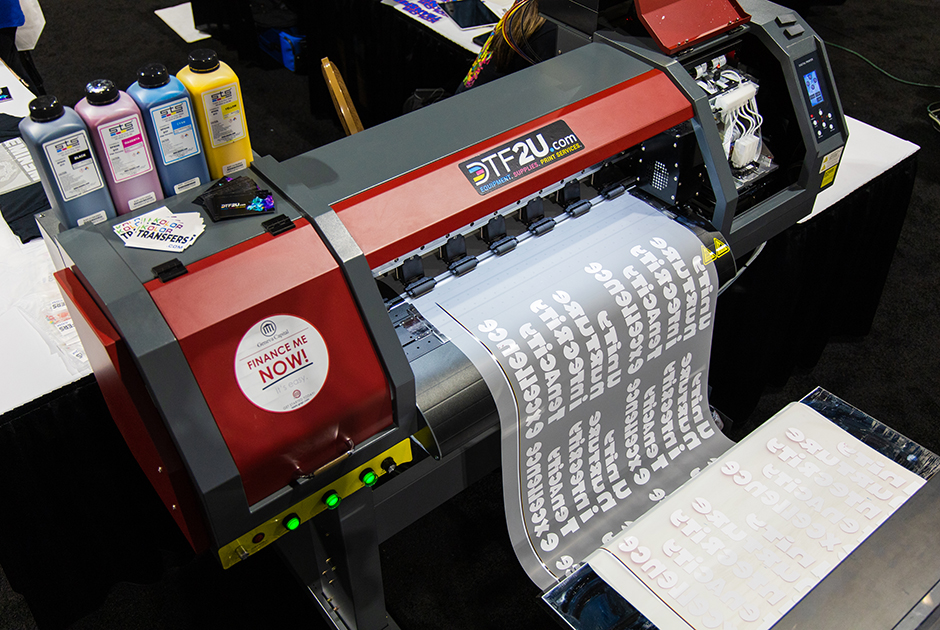

Understanding DTF Printing Essentials

DTF printing, a procedure that includes moving styles from a special movie to textiles using warmth and pressure, creates the structure of textile printing strategies. This ingenious method permits high-grade, lively styles to be seamlessly moved onto different materials with accuracy and detail. The initial step in DTF printing involves creating or selecting a design that will certainly be printed onto the fabric. This layout is after that published onto a special movie using a DTF printer, which utilizes specific dyes or pigments to make certain color precision and sturdiness.

Once the style is printed on the film, it is then meticulously placed onto the material, making certain proper positioning and positioning. The following essential step entails using heat and pressure utilizing a warmth press machine. This process triggers the dyes or pigments on the film, creating them to sublimate and bond with the textile fibers permanently. The outcome is a sensational, durable textile design that is washable, versatile, and resistant to fading. Generally, recognizing the essentials of DTF printing is important for grasping this contemporary textile printing method.

Picking the Right Fabric Products

Having established the fundamental concepts of DTF printing methods for fabric layouts, the following vital factor to consider lies in choosing the ideal textile products to complement this cutting-edge process properly. Additionally, the stretchability of these products can suit the heat transfer procedure entailed in DTF printing without distorting the style. By picking the right textile products, developers can make best use of the potential of DTF printing to produce magnificent and long-lasting fabric designs.

Understanding the Printing Process

To succeed in DTF printing methods for textile designs, understanding the printing process is important for attaining regular and top notch results. The temperature level, stress, and duration of heat application need to be meticulously regulated to guarantee correct bond of the layout to the textile. By sharpening each of these steps in the printing procedure, designers can continually create magnificent and resilient fabric designs with DTF printing methods.

Enhancing Layouts With Color Methods

Furthermore, experimenting with color gradients can bring a sense of movement and fluidity to the style. By blending shades flawlessly, a gradient effect can be accomplished, adding a contemporary and vibrant touch to the textile design. Additionally, utilizing color blocking techniques can create striking and bold visuals by comparing various strong colors in distinct sections of the layout.

In addition, including metallic or neon colors can give a distinctive and special element to the fabric style, making it stand apart and exhibit a sense of vibrancy. When tactically applied, these shade techniques can boost the general aesthetic charm of textile styles, making them much more memorable and exciting.

Troubleshooting Common DTF Printing Issues

After checking out different shade strategies to boost fabric layouts, it is essential to address common DTF printing issues that may arise throughout the manufacturing procedure. In addition, concerns with picture clearness and sharpness can occur due to low-resolution images or inappropriate printing strategies. By being mindful of these typical issues and executing the required troubleshooting steps, you can enhance the overall top quality of your DTF published textile styles.

Conclusion

In conclusion, mastering DTF printing strategies is crucial for developing sensational textile designs. By recognizing more helpful hints the fundamentals of DTF printing, choosing the right products, and improving designs with shade methods, one can achieve remarkable outcomes. It is necessary to fix common issues that might arise throughout the printing procedure to ensure an effective result. With practice and attention to detail, one can create special and attractive textile layouts utilizing DTF printing methods.

DTF printing, a process that involves moving designs from an unique movie to textiles utilizing warmth and pressure, forms the structure of fabric printing techniques.Having developed the fundamental principles of DTF printing methods for fabric layouts, the next vital factor to consider exists in selecting the proper fabric products to complement this ingenious procedure properly. By selecting the best fabric products, developers can make best use of the potential of DTF printing to create long-lasting and spectacular textile styles.

To stand out like it in DTF printing methods for fabric styles, understanding the printing procedure is crucial link for achieving consistent and premium outcomes. DTF Printing. By refining each of these steps in the printing process, designers can consistently generate sturdy and magnificent fabric layouts with DTF printing methods